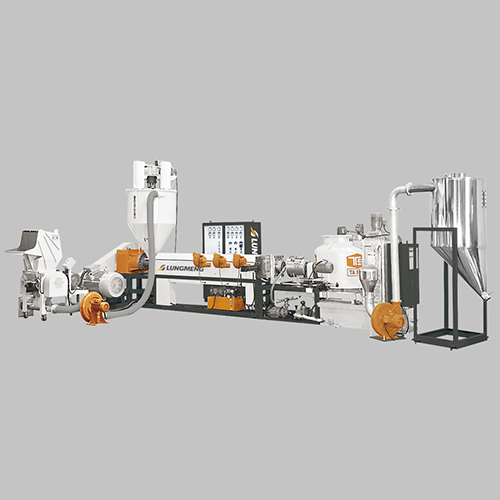

Two Stage Cutter Compactor Plastic Recycling Machine (KRIEGERi Series)

Categories : Plastic Pelletizer Machines

Compacting & feeding The high-speed compactor creates superior efficiency friction heat to compact the fluffy materials. Removed moisture during processed. Increase the highest throughputs for more productivity. Multiple Cooling Triple cooling sections – air cooling system, compactor body water cooling system and water spraying system. The operator can set the temperature of each to stably control the compactor’s temperature. Unrivaled Degassing Up to triple optional degassing zones equipped with vacuum pump. Maximize the degassing efficiency. Exhaust-Free Construct The unique development of two-stage extruder. A completely enclosed flow design, which prevents the molten polymer from releasing smoke. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. Cost Saving Energy cost saves up to 20%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

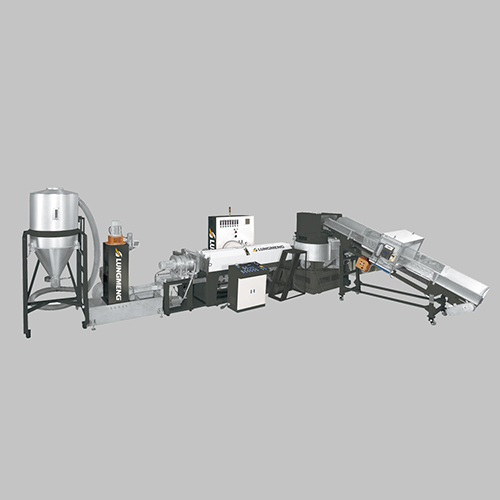

Force Side Feeding Plastic Recycling Machine (RECO Series)

Categories : Plastic Pelletizer Machines

Increasingly Feeding The force side feeding device creates a very stable feeding flow. With stable feeding, the main screw is always fully loaded with materials, which ensures the highest output performance. Increase the output capacity by up to 50%. More Labor-saving The feeding control system monitors the ampere and controls the feeding speed automatically. Only 1~2 operators are required for an entire plant. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. OUTSTANDING PERFORMANCE Increase the output capacity up to 50%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

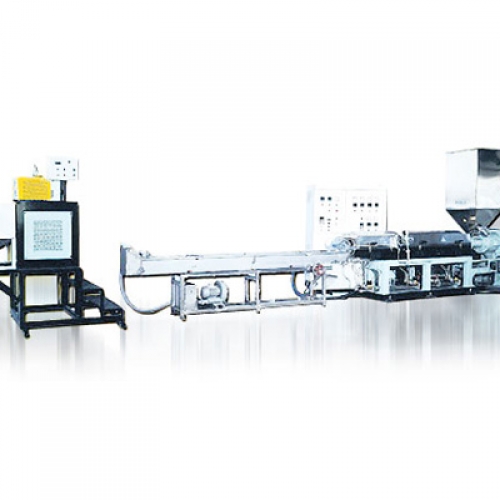

Plastic Recycling Machine - WTS Series

Categories : Plastic Waste Recycling Machines

WTS85, WTS100, WTS120, WTS150 RECYCLING PE/PP/ABS/PS

Two Stage Hopper Feeding Plastic Recycling Machine (Hi Series)

Categories : Bottle Recycling Lines

Economically Selection A valuable selection for clean materials, without pre-heating section for feeding device, this reduces the power consumption. The axle made by special steel with heat treatment. More tenacity and allows the materials to be fed sequence stably and also anti-bridging. Unrivaled Degassing Up to triple optional degassing zones equipped with vacuum pump. Maximize the degassing efficiency. Exhaust-Free Construct The unique development of two-stage extruder. A completely enclosed flow design, which prevents the molten polymer from releasing smoke. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. Cost Saving Energy cost saves up to 10%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

Two Stage Force Side Feeding Plastic Recycling Machine (RECOi Series)

Categories : Plastic Waste Recycling Machines

Increasingly Feeding The force side feeding device creates a very stable feeding flow. With stable feeding, the main screw is always fully loaded with materials, which ensures the highest output performance. Increase the output capacity by up to 50%. Unrivaled Degassing Up to triple optional degassing zones equipped with vacuum pump. Maximize the degassing efficiency. Exhaust-Free Construct The unique development of two-stage extruder. A completely enclosed flow design, which prevents the molten polymer from releasing smoke. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. OUTSTANDING PERFORMANCE Increase the output capacity up to 50%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

High-Speed Dyeing & Pelletizing Production Line

Categories : Compounding Lines

Suitable for masterbatch with fiber pelletizing, HDPE, LLDPE, LDPE, PP, PMMA, ABS, PC, Nylon, etc. Special screw design for compounding Changing material is easy Easy to operate Machine frame is very strong Customized screen changer

HF-FTO 3 In 1 Series:3 in 1 Pelletizing Extrusion / Extruder Pelletizer

Categories : Plastic Pelletizer Machines

Produced by experienced plastic recycling extruder machine manufacturer. Suitable for handling differences of materials. Suitable for processing most of the thermoplastic materials. Applicable materials Film or Flakes : PE、LDPE、LLDPE、HDPE、PP、PET、PS、PA、BOPP、ABS

HF-TS SERIES: Plastic Pellet Extruder ( Twin Screw )

Categories : Compounding Lines

This pelletizing equipment (Twin screw pelletizing extrusion) is mainly applied to the thermal polymer compounding field, and we offer customized compounding solutions for any requests. We supply the twin screw compound process with an appropriate dosing system in order to create a high quality output, and we can design a production line to meet the needs of customers based on the differences of materials. Applicable materials : PET、PA、PS、ABS、PEEK、PE、LLDPE、LDPE、HDPE、 PP、BOPP、TPU、TPE、TPV、TPR、RUBBER、FEP、SMA

Cutter Compactor Plastic Recycling Machine (KRIEGER Series)

Categories : Plastic Crushers

Compacting & feeding The high speed compactor creates superior efficiency friction heat to compact the fluffy materials. Removed moisture during processed. Increase the highest throughputs for more productivity. Multiple Cooling Triple cooling sections – air cooling system, compactor body water cooling system and water spraying system. The operator can set the temperature of each to stably control the compactor’s temperature. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. Cost Saving Energy cost saves up to 20%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

ABS/PP/PE Waste Plastic Recycling Making Machine

Categories : Plastic Waste Recycling Machines

ABS/PP/PE Waste Plastic Recycling Making Machine

Dyeing and Pelletizing Plant

Categories : Plastic Pelletizer Machines

• Model: TY-DB Series • Country of Origin: Taiwan • Applicable resin: PP, PE, ABS, PS. • Specific resin: PC, PET, ACRYLIC, NYLON. • Capacity: 50-1000 kg/hr